Some business challenges cut across the board regardless of your niche. For example, the markets and supply chains change constantly, and you have to figure out how to navigate them to keep your business afloat.

As a drug sponsor, keeping up with safety regulations and pivoting your business model to optimize costs can seem impossible.

Many companies with these and other competing priorities have been looking to outsource some of their non-core services. But is it applicable to every business?

What Is a Pharmaceutical CMO?

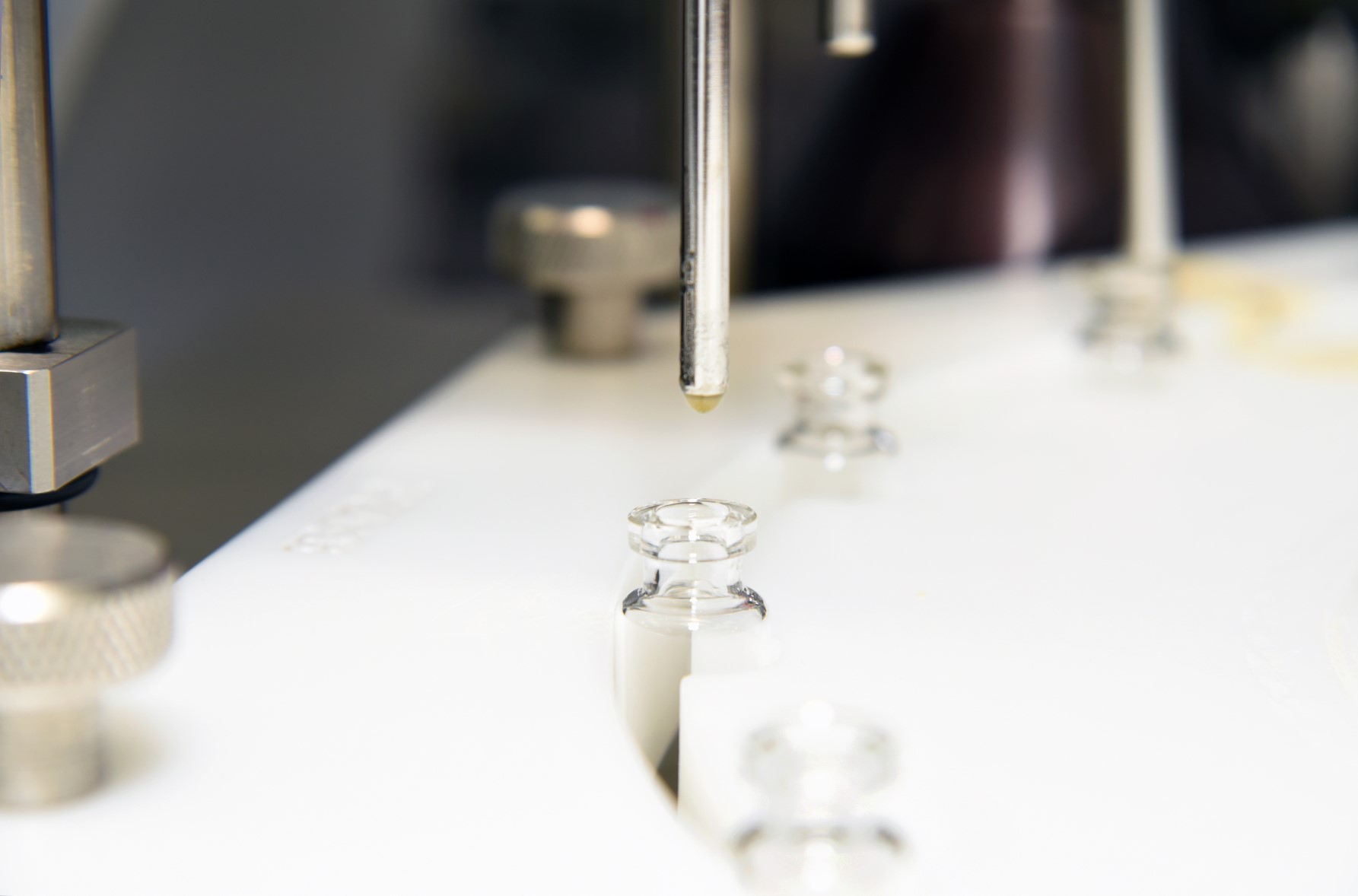

A pharmaceutical CMO is a business that delivers drug manufacturing and development services to companies in the pharmaceutical industry on a contract basis.

The major benefit of outsourcing to pharmaceutical CMOs is buying time needed to prioritize internal drug discovery capacities and enhance process efficiencies. In other words, getting your product to trial or market faster.

The pharmaceutical CMOs market is expected to grow at a CAGR of 7.29% by 2027. This growth is attributed to the rising demand for generic medicines and biologics, the massive capital required to run businesses in this field, and the strenuous manufacturing regulations.

Why Should You Use a CMO?

A typical drug company has many moving parts and competing priorities. Beyond drug development, you must have functional management, marketing, and other departments and a source for funding.

CMOs can specialize in different areas of the drug manufacturing process, including research and development, manufacture of active pharmaceutical ingredients, analytical testing, and manufacture of commercial products. A pharmaceutical CMO takes some of these demands off your plate so you can focus on what you do best.

Also, as the pharma industry moves to more complicated biopharmaceuticals and personalized medical products, the demand for more technical manufacturing and higher capacity continues to grow. It’s difficult to meet these demands alone.

A CMO provides these services in the following areas of drug development and manufacturing:

- Pre-Formulation

- Formulation Development

- Stability Studies

- Method Development,

- Pre-Clinical And Phase I Clinical Trial Materials,

- Late-Stage Clinical Trial Materials

- Formal Stability

- Commercial Production

- Regulatory assistance

Outsourcing these services comes with many proven benefits:

Cutting Costs and Reducing Time to Market

The average cost of developing a new drug falls between $314 million to $2.8 billion. CMOs come in with their own equipment, highly trained operators, and expertise, yet charge you much less than you would spend to manufacture it yourself.

Scalability

If you own a research and testing company, you can’t expand into manufacturing without spending considerable time sourcing for funding.

Even if you succeed, you’d have to gauge the demand for your drug and decide how much capacity you need to produce it. A higher demand than you bargained for makes your supply inadequate. Producing more than the demand leaves you paying for equipment, facilities, and human labor you don’t need.

A CMO makes expansion much easier because they have the necessary facilities, labor, and equipment.

Spend Less on Equipment and Facility Maintenance

Tech advancements in the pharmaceutical industry move just as fast as in other industries. They are also tied to your ability to produce high-quality products and compete on a level playing field with competitors.

However, they need money to adopt and use. Engaging a CMO shifts these responsibilities to the CMO, significantly reducing your costs.

Also, operators working for CMOs must be highly trained to ensure the quality of the product. It can take up to a year for someone to be fully trained. The CMO handles this need for you.

Optimize the Supply Chain

Supply chain issues occur all the time for different reasons. CMOs are better placed to handle these disruptions because they have built up inventories and good relationships with suppliers.

Plus, they often know where to source products when there’s a shortage. If necessary, they can shift production to another facility.

What Should You Look For in a CMO?

CMOs make your responsibilities lighter, but you risk your market share and public trust if you choose the wrong CMO. These risks are even higher if your product requires aseptic sterile manufacturing. Here are some qualities to look for to minimize these risks:

- A Culture That Aligns With Your Culture

A good relationship is vital for working with a CMO. But you can only build a thriving relationship if your culture aligns with theirs.

The best way to gauge a CMOs culture is by conducting a site visit and experiencing it firsthand. It’ll give you a feel of their values, how employees are treated, and even how client-centric they are.

Additionally, cultural differences do not only create language issues such as misunderstandings and misinterpretations. They clash with beliefs, knowledge, and skills. These things have a spiral effect on your company. A good culture fit should make your CMO feel like an extension of your team.

- Demonstrable Expertise

Ensure their capabilities match up with your needs. Don’t just look at their experience with the type of manufacturing you need or with the same type of product as yours. Make sure they’ve successfully gotten it to trial or market in the same volumes that you require.

- Expert Tech and Equipment Capabilities

Each product has a distinct list of critical characteristics and needs. Ensure your CMO has the facilities and equipment that satisfy those needs.

- A Solid Cross Contamination Strategy

CMOs work for different clients simultaneously. This fact creates multiple opportunities for cross-contamination. A facility should always have controls in place to mitigate cross-contamination. Ensure these controls are adequate to protect your product.

- Find Multiple Trustworthy References

Drug manufacturing is one of the most safety-driven industries. Ask your potential CMO to show testimonials under a non-disclosure agreement to gauge their trustworthiness.

- Sound Quality and Control Audit Functions

Make sure to perform technical visits and quality audits of your potential CMO. During these, you can ensure that their work processes and systems align with what you need, as well as ensure their regulatory history is sufficient. will your CMO assure you that what you get is high quality? Please take advantage of your interviews to ask about their work processes and systems used to gather and analyze production data.

The rule of thumb is to apply this checklist to the specifics of your company so you can get a perfect fit.

What Can You Expect From a CMO?

CMOs supply different drug manufacturing services to the pharmaceutical and biotechnology industries, from drug development to full-scale production.

The scope of work differs from organization to organization. You can hire some to manufacture small quantities of materials for research and development, then larger quantities for clinical studies, and lastly, for full-scale production.

While your needs may be different from others –for example, an aseptic sterile manufacturing business versus a topical medicine manufacturing company -you should expect these services from a CMO:

- Manufacturing from beginning to end

- Drug coating (If your drug requires it)

- Labeling

- Packaging and serialization

- Distribution, either wholesale or directly to consumers

In a nutshell, a CMO should help you avail new drugs and treatments to people who need them faster.

CMOs are a much-needed asset in an industry where timing and quality are top priorities. They also contribute to clinical research, helping provide optimum healthcare worldwide.

Further, they bridge production gaps by providing skills, facilities, and technologies many pharmaceuticals need help accessing. This way, they give you a competitive advantage and ensure you meet consumer needs as they expect you to.

Are you looking for a CMO in Aseptic sterile manufacturing? Afton Scientific is a highly-experienced cGMP Contract Manufacturing Organization (CMO) specializing in sterile injectables. We are committed to safety control, fast-turn-around, and delivering quality that helps you stay ahead of your competitors. Learn more.